Compressed Air System Design

What is Compressed Air?

Compressed air is a form of stored energy generated by compressing atmospheric air to a higher pressure than its ambient state. The process involves using air compressors that utilize various mechanisms.

Working Principle of Compressed Air Systems

The primary working principle of a compressed air system involves drawing in ambient air through an intake, compressing it to the desired pressure, and storing it in air receivers. The compressed air then passes through air dryers and filters to remove moisture and contaminants before being distributed through the network of pipes to end-users.

Compressed Air System Components

1. Air Compressor

The air compressor stands as the heart of any compressed air system. It is responsible for drawing in atmospheric air and converting it into compressed air by increasing its pressure. Air compressors come in various types, including rotary screw, reciprocating, and centrifugal, each catering to specific industrial needs. These powerful machines play a vital role in providing a continuous and reliable source of compressed air for various applications.

2. Air Dryer

Moisture in compressed air can lead to equipment corrosion and damage, making air dryers an essential component in the system. Air dryers remove moisture from the compressed air, ensuring the air remains dry and clean before it reaches the end-users. There are different types of air dryers, such as refrigerated, desiccant, and membrane dryers, each offering unique advantages based on the specific application requirements.

3. Air Receiver Tank

The air receiver tank, also known as an air storage tank, plays a crucial role in maintaining system stability and optimizing performance. It acts as a buffer by storing the compressed air and smoothing out pressure fluctuations, ensuring a consistent and steady supply of air during peak demands. Additionally, the air receiver tank allows the compressor to run more efficiently by reducing the number of start-stop cycles, which can help conserve energy and prolong the compressor’s life.

4. Air Filters

Air filters are critical components that ensure the compressed air is free from contaminants and impurities. They remove particles, dust, oil, and other pollutants, safeguarding downstream equipment from potential damage and maintaining air quality. Regularly changing and maintaining air filters is essential to ensure the system operates at peak efficiency and meets industry standards for air quality.

5. Air Intake Filter

The air intake filter is specifically designed to protect the air compressor by preventing dust, debris, and other large particles from entering the system. It plays a crucial role in ensuring the longevity and optimal performance of the air compressor. Regularly inspecting and cleaning or replacing the intake filter is necessary to avoid clogging and maintain smooth air intake.

Especially in harsh environments, such as excessive dust, the pre-filter is necessary.

6. Pipes and Connections

The distribution network of pipes and connections forms the backbone of the compressed air system, facilitating the transportation of compressed air from the compressor to various end-users. Properly sized and optimized piping systems are essential to minimize pressure drops and ensure efficient delivery of compressed air. High-quality materials and leak-free connections are vital to prevent air losses and optimize system performance.

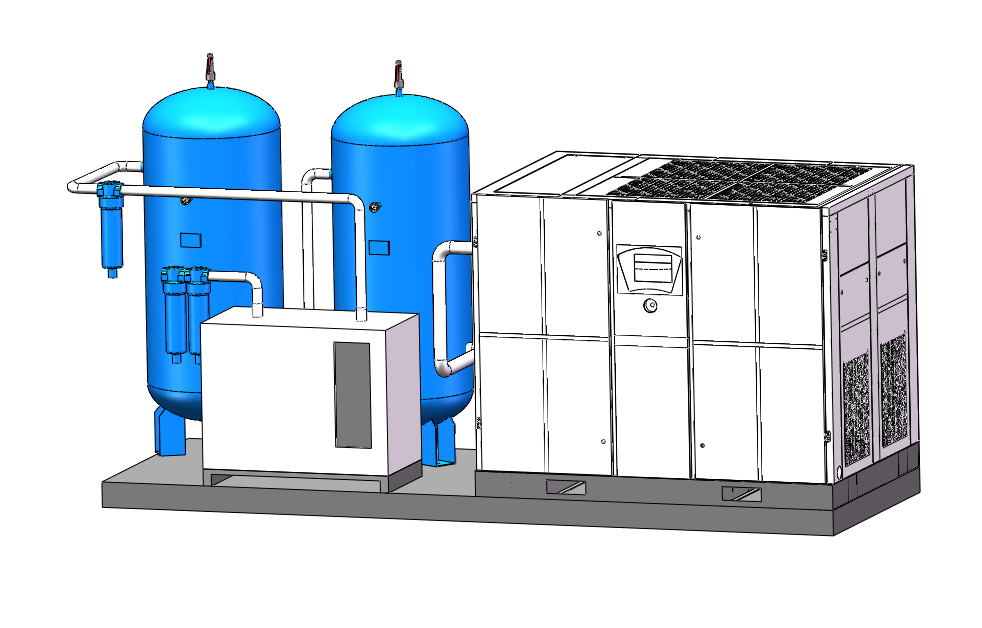

Airpressa’s Complete Compressed Air Systems

Airpressa provides complete compressed air systems, including air compressors, air dryers, air tanks, and air filters. And we provide more flow options 7.5kw (10hp) – 250 kw (350hp), in order to meet the choice of most industries and customers.

The most popular and common compressed air systems:

- 7.5kw (10hp)

- 15kw (20hp)

- 22kw (30hp)

- 30kw (40hp)

- 37kw (50hp)

- 45kw (60hp)

Large industrial compressed air systems:

- 200kw (270hp)

- 250kw (350hp)

Air Compressors

Our rotary screw air compressors have always been known for their stability and reliability. With a low failure rate and minimal maintenance costs.

Air Dryers

Our refrigerated air dryers are available in a variety of sizes and capacities, allowing you to select the model that best suits your compressed air systems.

Air Tanks

Invest in Airprssa’s compressed air receiver tanks and experience the advantages they offer in terms of safety, capacity, expertise, and convenience.

Air Filters

Airpressa provides the complete set of three-stage air filtration system: Q(3 μm), P(1 μm), S(0.01 μm), capturing particles as small as 0.01 microns.

What Should be Careful in the Compressed Air System Design?

Applicable to Your Industry

In the design of air compression systems, a fundamental consideration is understanding the specific application requirements. Different industries and processes demand varying levels of compressed air volume, pressure, and quality. Thus, a thorough assessment of the end-users’ needs will ensure the system is tailored to meet those requirements effectively.

Proper Sizing and Capacity Planning

Accurate sizing and capacity planning are critical factors in designing an efficient air compression system. Undersized compressors may struggle to meet your air demand.

Conversely, oversized compressors may result in unnecessary energy consumption and higher operating costs.

Air Quality and Filtration

Considering the quality of the compressed air, especially for sensitive applications such as food processing or electronics manufacturing. Selecting appropriate air filters and dryers is necessary to remove contaminants, moisture, and oil to meet the required air quality standards.

At this time, a oil-free air compressor is the best choice.

Energy Efficiency and Control

Designing an energy-efficient air compression system can lead to substantial cost savings. Utilizing advanced control systems, such as the variable speed air compressor, it allows the compressed air system to match output with actual demand, reducing energy wastage during periods of low consumption.

Optimal Piping and Distribution Network

Properly sized and optimized piping reduces pressure drops and minimizes energy losses. Additionally, using high-quality materials and ensuring leak-free connections are crucial in maintaining system integrity and reducing maintenance efforts.

Noise and Environmental Considerations

Air compressors can generate noise during operation, potentially impacting the surrounding environment and workplace. Integrating noise reduction measures and considering the compressor’s location can help mitigate noise levels and improve the work environment.

Ventilation and Heat Dissipation

As compressors operate, they generate heat, and efficient cooling mechanisms can maintain optimal performance and extend the lifespan of the equipment.

Inadequate ventilation can lead to temperature build-up, causing the compressor to operate at elevated temperatures. This can negatively impact the compressor’s efficiency and performance over time. Designers must ensure that the compressor’s location allows for adequate air circulation and proper heat dissipation.

Allow Sufficient Space for Setup, Debugging, and Maintenance

When designing the air compression system, it is essential to allocate sufficient space for the compressor’s installation and other system components. A cramped and cluttered environment can hinder maintenance tasks, make inspections challenging, and potentially lead to safety risks.

Furthermore, by allowing ample space, technicians can comfortably access the compressor, reducing the risk of accidents during maintenance or repairs. A well-organized layout also facilitates routine inspections and system adjustments, enhancing overall operational efficiency.

A LEADING MANUFACTURER OF

ROTARY SCREW AIR COMPRESSORS

Airpressa is a leading manufacturer, exporter, and solution provider of industrial air compressors in China. With a rich history dating back to the year 2000, we have been consistently delivering high-quality air compressors and related products to meet the diverse needs of our global clients.

At Airpressa, we are not just about manufacturing air compressors. We are also a trusted partner and solution provider for our clients. We work closely with them to understand their unique requirements and offer customized solutions to meet their specific needs.